The issue of electrocoat cracking on sheet metal bent at 90 degrees is one that has plagued the industry for years. It is a significant problem that results in costly rework and scrap for manufacturers. There are several reasons why electrocoat cracking occurs on bent sheet metal, and the primary one is the deformation of the coating on the concave surface during the bending process. The deformation creates a tensile stress on the surface of the coating, which leads to cracking during the curing stage.

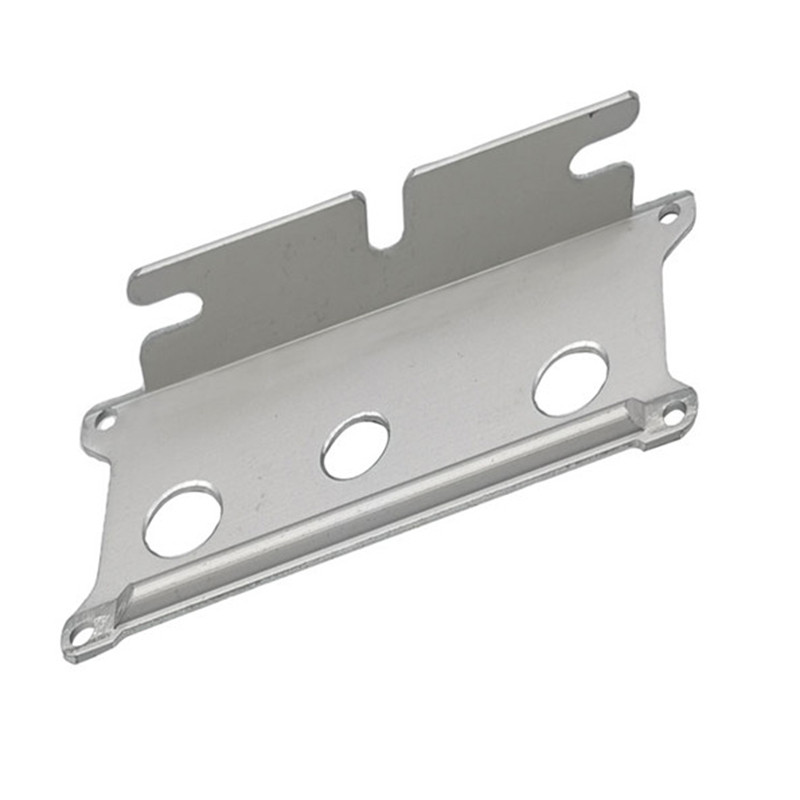

Another reason for electrocoat cracking is the inadequate bend radius of the sheet metal. If the radius of the bend is too small or the sheet metal is not adequately prepped, it can lead to stress concentrations that crack the coating. Furthermore, the use of improper forming tools can also contribute to the occurrence of electrocoat cracking on bent sheet metal.

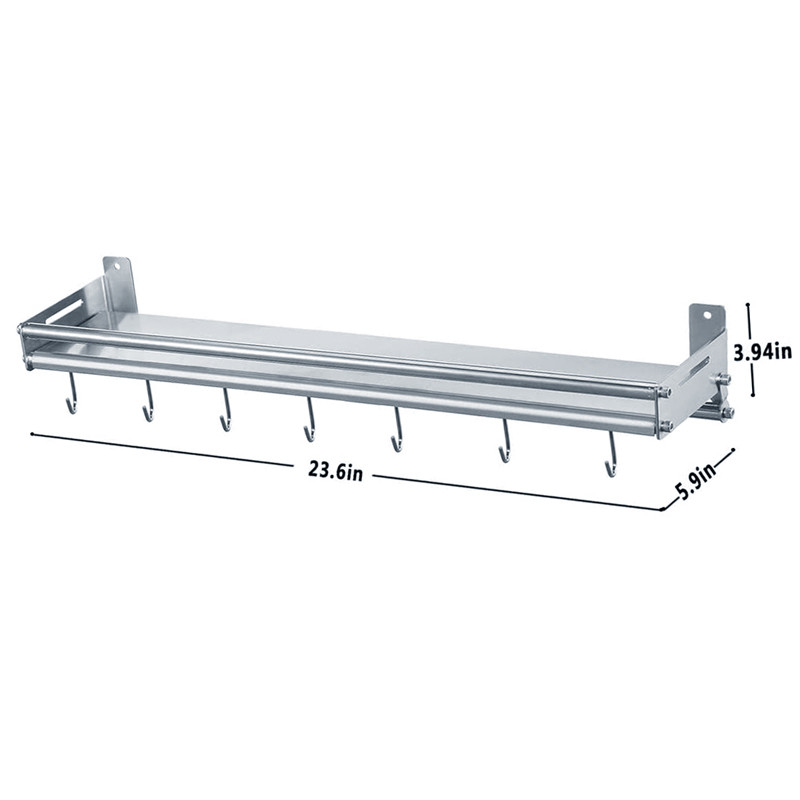

To prevent electrocoat cracking on bent sheet metal, it is essential to follow specific processing steps in the manufacturing process. One of the key steps is properly prepping the metal surface before application. This involves cleaning and treating the surface to prevent contamination, oxidation, and other factors that can negatively impact coating adhesion. Additionally, manufacturers should consider using a specially designed forming tool to ensure that the sheet metal is adequately bent without causing stress concentrations.

Another method to prevent electrocoat cracking on bent sheet metal is the use of simulation technology. This enables manufacturers to simulate the manufacturing process and predict areas of stress concentration before production begins. Using simulation software, manufacturers can make design changes to minimize stress concentrations and improve the overall quality of the product.

In conclusion, electrocoat cracking on bent sheet metal is a significant issue that manufacturers must address to produce high-quality products. The deformation and inadequate bend radius are some of the reasons why this occurs. To prevent this problem, manufacturers should take specific steps, including surface preparation, using specialized forming tools, and simulation technology, to ensure a high-quality finished product. It is essential to incorporate these measures to ensure the bent sheet metal processing meets industry standards while also maintaining quality and performance expectations.