Sheet metal has been a staple material for industrial and commercial applications for decades, and it continues to be widely used today thanks to its versatility, durability, and ease of machining. However, traditional sheet metal fabrication methods such as stamping, punching, and shearing have certain limitations when it comes to precision, speed, and complexity. Fortunately, there is a game-changing technology that is revolutionizing the way non-ferrous metals are cut, shaped, and engraved: laser cutting.

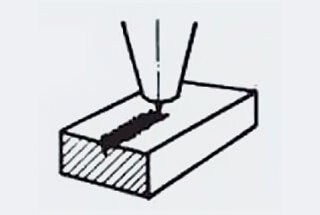

Sheet metal laser cutting involves using a high-powered laser beam to melt, burn or vaporize a precise pattern on a sheet of metal. Laser cutting machines are controlled by computer-assisted design (CAD) software that allows for precise, repeatable, and fast cutting of metal pieces in various geometries and thicknesses. The result is a burr-free, clean-cut edge that requires minimal post-processing and can be used for a variety of applications, including aerospace, automotive, medical, architectural, and artistic.

Sheet metal laser cutting is particularly beneficial for non-ferrous metals such as aluminum, brass, copper, and titanium, which are valued for their lightness, conductivity, strength, and corrosion resistance. These metals are used extensively in industries such as electronics, aviation, marine, construction, and jewelry, where precision and aesthetics are critical factors. Laser cutting can also be used for non-metallic materials such as plastics, wood, and textiles, expanding its range of applications and versatility.

In Forrestdale, WA, Sheet Metal Laser Cutting is a non-ferrous metals business that offers laser cutting services for various industries and applications. The company specializes in cutting aluminum, brass, and copper sheets up to 6mm thickness and 3000x1500mm size. The company uses state-of-the-art laser cutting machines that can achieve cutting speeds of up to 1m/min and cutting precision of up to 0.02mm. The company also offers a range of secondary services such as bending, welding, polishing, and powder coating to complete the fabrication process.

Sheet Metal Laser Cutting has a team of experienced engineers and technicians who can design, program, and execute custom laser cutting projects based on clients' specifications and requirements. The company has a quick turnaround time and offers competitive pricing for its services. Whether you need a single prototype or a large-scale production run, Sheet Metal Laser Cutting can deliver high-quality, accurate, and reliable metal parts that meet your needs.

Sheet metal laser cutting offers many advantages over traditional fabrication methods. For one, it can cut complex shapes, designs, and patterns that would be difficult or impossible to achieve with conventional tools. Laser cutting can also produce very small, accurate cuts that do not require any additional processing or finishing. This can save time, money, and resources in the production process. Additionally, laser cutting does not produce any physical contact or mechanical stress on the metal, minimizing distortion, warping, or metallurgical changes.

Furthermore, laser cutting can be fully automated and integrated into a work cell or a production line, reducing labor costs and improving efficiency. Laser cutting machines can be programmed to run 24/7, making them ideal for high-volume manufacturing. They can also be operated remotely, allowing for off-site monitoring and troubleshooting.

In conclusion, sheet metal laser cutting is a technology that is transforming the way non-ferrous metals are fabricated and used in Forrestdale, WA, and beyond. It offers precision, speed, and flexibility that were previously impossible, making it an ideal solution for various industries and applications. Sheet Metal Laser Cutting is a reliable and experienced laser cutting service provider that can help you achieve your metal fabrication goals. Contact us today to learn more about our services and how we can help you with your laser cutting needs.