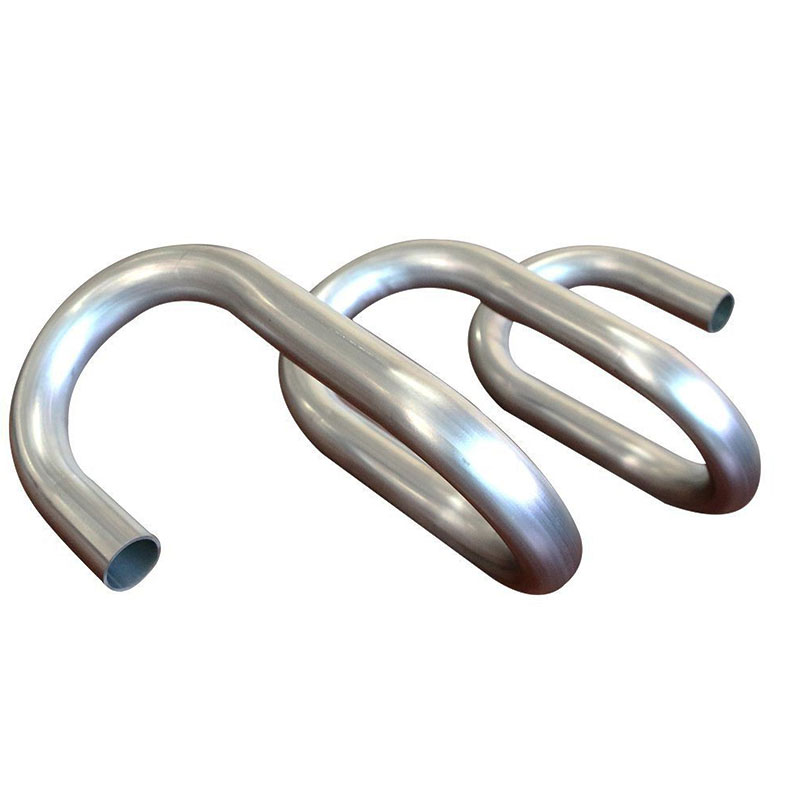

There are various methods that fall under tube bending such as form-bound and freeform-bending procedures, and heat-supported or cold forming procedures. Whatever the method, it's important that the techniques used adhere to industry standards and are suitable for the type of materials being used.

Form-bound tube bending refers to the process of utilizing a bend die to form curves on the tubing or pipes. This method involves forcing the material being worked on against the bend die till the desired shape is achieved. On the other hand, freeform-bending is more fluid in that it allows for the technician to mold and shape the material without the rigid use of a bend die.

Heat-supported tube bending is a process that makes use of heat to soften the material being worked on. The technician will then mold the material into the desired shape. Cold-forming, on the other hand, is more precise and delicate, typically used for brittle and non-malleable materials. This process allows for the materials to be forged into shape without the use of heat, which is helpful when working on materials that are highly temperature-sensitive or highly reactive.

When deciding which method to use, factors such as available resources, materials, and required shape need to be considered. In addition, the size and shape (and the degree to which it will be bent) must also be considered, as this will have a significant impact on which method will be most effective.

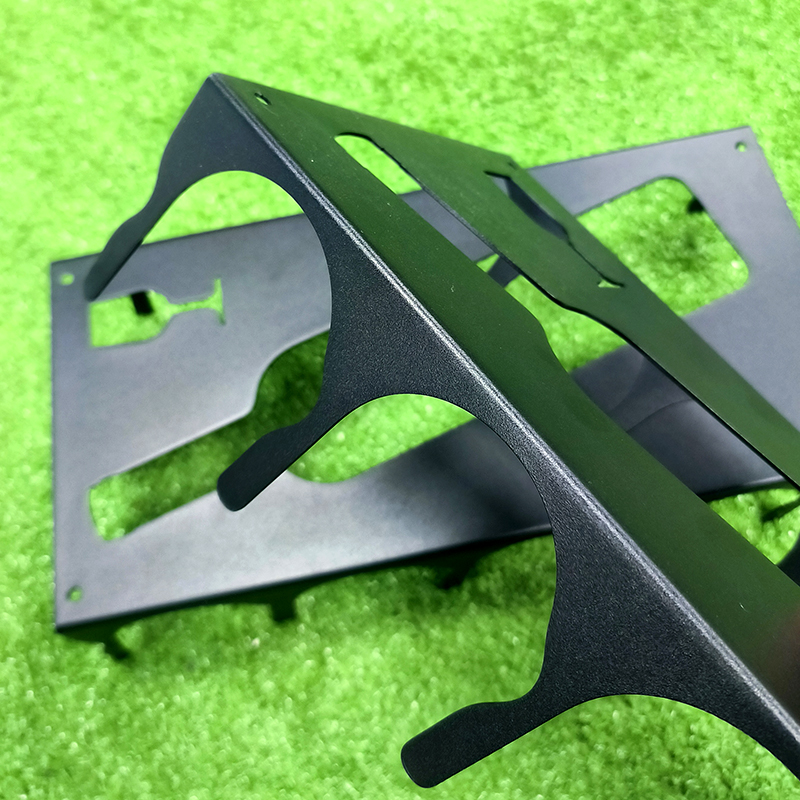

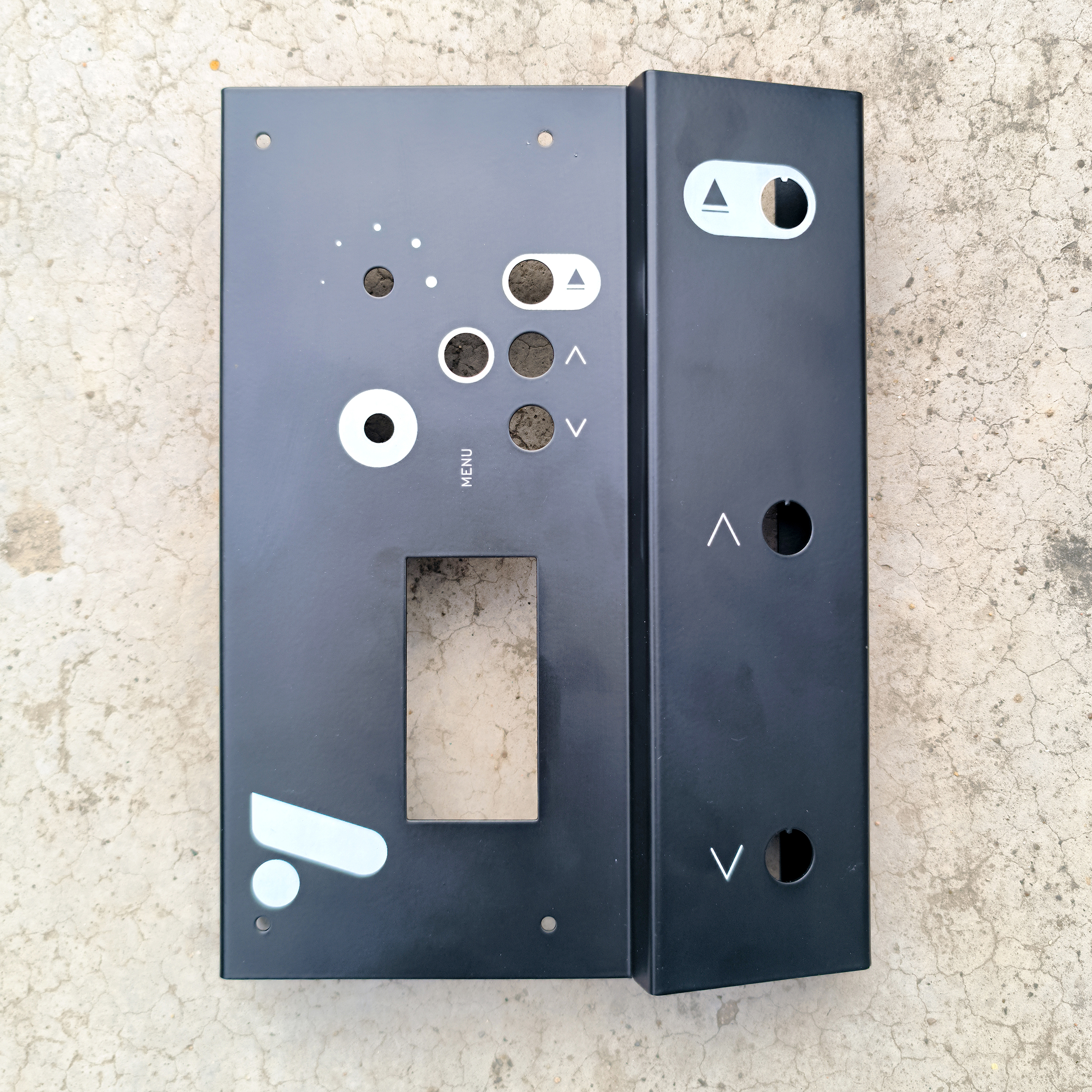

Some of the key industries that use tube bending include aerospace, automotive, architecture, and construction. In aerospace, for instance, it is used for manufacturing frames to support aircraft structures, fuselage, and landing gear. In the automotive industry, it's common in the manufacturing of exhaust pipes, fuel lines, and brake systems. In architecture and construction, it's used for railings, staircases, supports, and other structural components.

In conclusion, tube bending is an essential process in metal forming. With advanced technology and innovation in materials, the process has evolved to deliver highly precise and consistent results. It's important to understand that there is no one-size-fits-all approach to tube bending, and as such, it's crucial to consider factors such as materials, shapes, and available resources when making a decision. Industries like aerospace, automotive, architecture, and construction depend on this process to manufacture a wide range of products. Looking to get your materials expertly bent? Look no further than us for all your tube bending needs! Contact us today for more information.

Keywords: Tube bending, Form-bound tube bending, Freeform-bending, Heat-supported tube bending, Cold-forming, aerospace, automotive, architecture, construction.